Diesel Generator Oil Type

Each engine model requires an oil with specific properties. For generators, it is selected according to the type of fuel (gasoline or diesel) and the engine operating conditions. Diesel power units require oils of special quality. What kind of oils? Let’s analyze in detail.

The modern market offers a variety of models of diesel generators. For private homes, units with a capacity of 5 to 15 kW are used, as well as they are suitable for professional use (welding or other works). Industrial sites need a more powerful power source – diesel generator sets, a capacity of 15 kW and above.

For What Reason the Diesel Generator Needs a Special Oil

The peculiarity of the diesel engines is a strong thermal stress, the emission of soot and oxides – this is their difference from gasoline engines. In addition, due to the high pressure, which occurs in the combustion chamber, the oxidation process and, therefore, the oil aging is accelerated. At the same time diesel oils produce soot (ash) if the engine is operated at high revs.

For this reason, generator oils are characterized by enhanced detergent properties. This is ensured by its content of strong alkaline binding additives, which break down solid deposits. Manufacturers add components to these oils that effectively neutralize oxidation products. Whereas for gasoline units, the more important properties are the strength of the oil film and weak burnout.

To understand which oil for a generator is better to buy, you need to take into account some factors:

- fuel in diesel electric generators does not burn out completely, and during combustion emits a lot of soot;

- the peculiarities of such engine operation result in the lubricant properties changing with time, the ageing process (contamination by various impurities, particles of worn-out parts and burnt fuel, water, etc.). At the same time the necessary additives are also triggered;

- increased amount of alkaline, dispersing and detergent additives ensures durability of diesel generators operation;

- the oil for the diesel generator motor must provide enhanced protection of piston rings, cylinder walls, liners and other parts from mechanical wear and tear. Therefore the strength of the oil film must be able to withstand high mechanical loads without losing its lubricating properties.

Important! In a worn engine the oil will age very quickly.

Read also: How To Start A Generator For The First Time?

What Oil to Choose for Power Plant Operation, Expert Recommendations

Modern manufacturers produce oils that have unique properties, that is, work equally well in diesel and gasoline generators, moreover, at any time of the year. Yet the market offers a large number of oils for diesel engines directly. When buying oil, you should be guided by:

- viscosity;

- marking;

- composition (mineral, synthetic);

- grade.

Let’s analyze in order:

- As for oil viscosity, the higher it is, the more protection the lubricant creates on the parts during friction. Here we should consider that too thick grease is difficult to penetrate into the gaps between the parts. Temperature changes its thickness (the lower the temperature, the thicker the oil);

- Each generator oil is labeled by engine type, class and type of engine. The letter S marks the lubricant for gasoline units, the letter C ─ for diesel units. If the label contains a combination of both letters separated by a fraction (S/C), it means it is a universal material, suitable for both types. The next letter serves to specify the operating conditions. It is better to fill into the diesel generator the oils marked CD, CE, CF-4 (the oils marked with the second letters A, B, C are considered the low class grease, it is better not to buy them). At the same time for two-stroke and four-stroke engines a different lubricating mixture must be used. Manufacturers show the relevant information in the instructions;

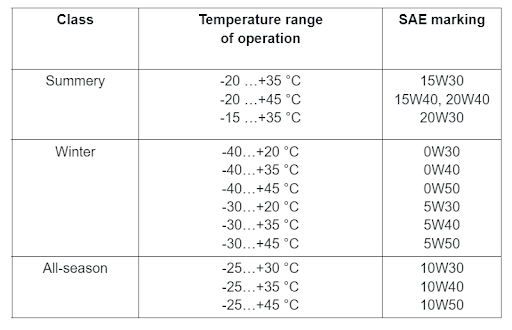

- According to the composition, lubricants are divided into mineral synthetic and semi-synthetic. Manufacturers add different additives to them, changing such characteristics as viscosity and density. Thus, at positive air temperatures, experts recommend using a mineral composition. However, at negative temperatures, it is able to crystallize and the unit will not start. Often it is necessary to change one kind of grease for another. In this case it is necessary to drain it all out and pour in another one. To make it easy to decide the choice, oils are marked according to the SAE standard.

This table shows only a general approach to choosing the right lubricant. In fact, each manufacturer gives detailed recommendations on the properties of the lubricant and additives, which are selected according to the operating hours and time of operation of the device, its wear in the instructions for their product. Note that there is no fundamental requirement for the type of oil used. Mineral oils are cheaper and, if it matches the viscosity and class, you can safely choose it. The widespread opinion that in modern diesels only synthetics should be used is unfounded. If the requirements coincide, it can provide engine life until the next service. At the same time the synthetic and semi-synthetic has more stable characteristics and a high technological level, more effectively ensures the engine operation and works better at low temperatures. The consumption of such grease is less compared to mineral. A good solution can be the use of semi-synthetic oils on the criterion of “price/quality”.

Important! Every second need in the diesel generator repair is connected with the wrong or low-quality lubricant.

Peculiarities of Diesel Generator Maintenance at the Oil Change

When using multi-temperature grease of the 10W30 type (SAE) its consumption increases significantly as soon as the temperature over the board is +4℃. Specialists warn that in this case you must constantly monitor the oil level and top up if necessary.

A very important stage in the operation of diesel generators is the correct periodicity of the lubricants replacement.

The first lubricant change should be made after 20 hours of operation of the unit. During this period, you should not load it at full power. At this stage, the lapping of the parts should take place. Further oil change should be as follows:

- mineral oil after every 50 hours of operation;

- synthetic oil every 100 hours.

Step-By-Step Instructions for Changing the Oil in a Diesel Generator

To change the oil, you need to:

- warm up the generator;

- find and clean the oil drain plug;

- loosen the container to drain the waste;

- unscrew the plug and carefully drain the used lubricant;

- tighten the oil plug securely;

- pour in new oil.

Note: Waste must not be poured out arbitrarily, it is collected in special containers and handed over to the collection and recycling points.

Read also: What Power Generator Do I Need?